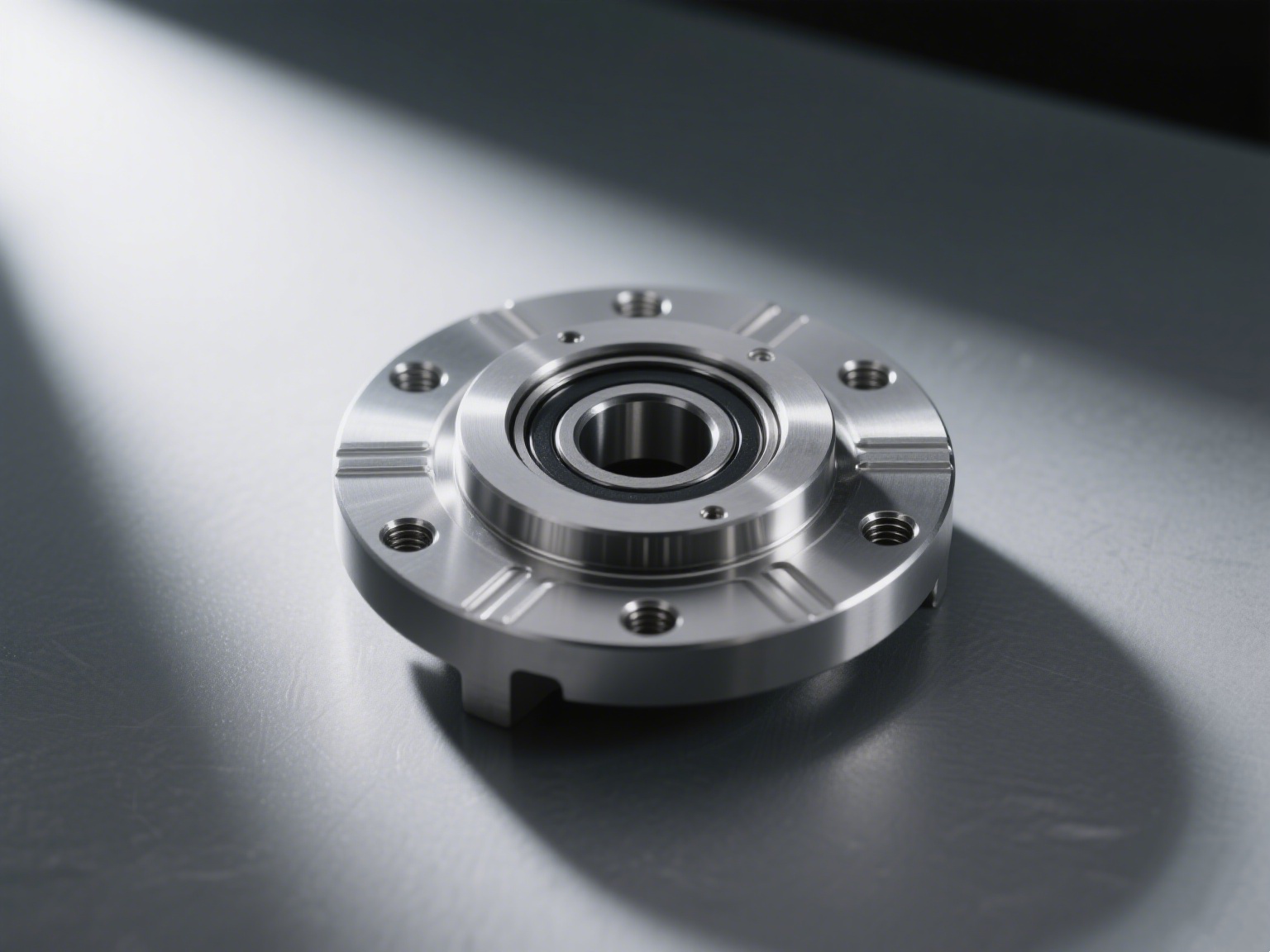

Precision Casting Aluminum Parts

The Power of Aluminum CastingIn the dynamic world of modern manufacturing, aluminum casting sta...

- Customized

- Precision Casting

- Customized

- Informations

- Description

The Power of Aluminum CastingIn the dynamic world of modern manufacturing, aluminum casting stands as a true game-changer, revolutionizing industries with its unparalleled versatility and efficie

The Power of Aluminum Casting

In the dynamic world of modern manufacturing, aluminum casting stands as a true game-changer, revolutionizing industries with its unparalleled versatility and efficiency.

At ShanFeng, we take immense pride in being at the forefront of this technological marvel, offering top-notch aluminum casting solutions that redefine excellence.

Casting is a common thermal processing technology for metals. It can process metal materials into parts or blanks with certain shapes, dimensions and properties.

The principle of casting is to melt the metal into a liquid, then pour it into a cavity with a specific shape. After cooling and solidification, the required casting is obtained through cleaning treatment.

There are mainly two categories of casting methods: sand casting and special casting.

Sand casting refers to the casting that uses natural sand or artificial sand as the main molding material. It has a simple molding process and low cost, and is suitable for castings made of various materials and specifications.

Special casting refers to the casting that uses other materials or methods other than sand as the molding material. It has a precise molding process and high quality, and is suitable for castings with complex shapes or high requirements. Special casting can be further divided into metal mold casting, investment casting, ceramic mold casting, centrifugal casting, die casting, etc.

Casting fills the metal in a liquid state, and can manufacture parts with complex shapes and multiple internal cavities. It has a wide adaptability, flexible production, and can use various metal materials. It has a low cost and high efficiency.

However, casting also has some disadvantages. For example, during the melting and solidification process of the metal, defects such as oxidation, inclusion and segregation are likely to occur, which will affect the structure and properties of the metal. The internal structure of the casting is uneven, and there are defects such as air holes, cracks and shrinkage cavities.

Casting is mainly applied to the fields of agriculture, construction, water conservancy, mining, light industry, home appliances, etc. Common castings include pipe fittings, flanges, pump bodies, valve bodies, machine tool beds, frames, fan impellers, motor casings, pressure vessels, stoves, cookware, ironworks, sculptures, etc.

Take a look at some of the amazing projects we've worked on, and see for yourself the power of aluminum casting.

Please contact us today to learn more about our services and how we can help you take your business to the next level.

Let's unleash the power of aluminum casting together!

| Type | Precision Casting | Entrance size | Customized |